- CHANNEL SPRINGS & SEAT PLATES

- COMPRESSOR VALVES VALVES

- VALVE PLATES, SPRINGS & FINGER VALVES

- HIGH WEAR RESISTANT PTFE & NON METALLIC PARTS

- PISTON RINGS

Premium quality hardened & tempered martensitic stainless steel alloyed with molybdenum & precision manufactured channel springs are offered for compressor valves to their exacting specifications

- High strength

- Very high fatigue strength under bending and impact stress

- Excellent surface finish

- High compressive residual surface stress

- Low levels of non-metallic inclusions

- Good wear resistance

- Corrosion resistant

- Super flatness to ensure zero leakage through slot sides

- Correct thickness to ensure zero leakage through slot sides

- Correct slot width as per OEM specifications

- Correct length positioning to ensure equal & adequate area from guide.

- Perfect PCD of holes to ensure reversibility of plates

- Low heat generation & less energy consumption due to non leakage.

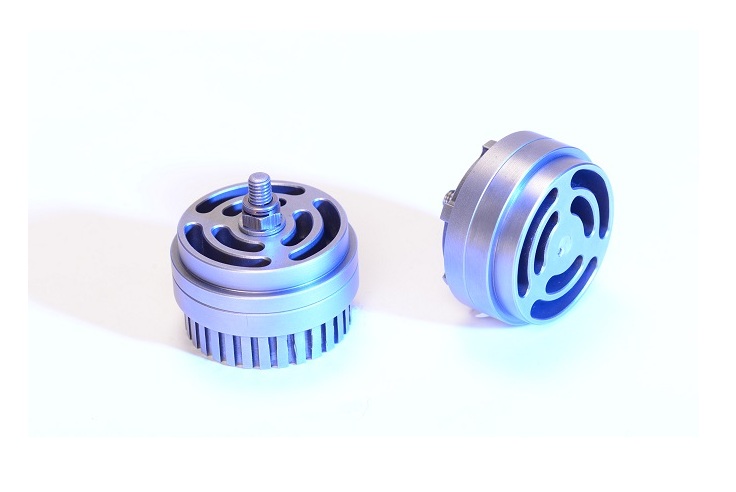

We offer a complete range of precision-machined compressor valves. Throughout the years, our valves have consistently proven their ability to assure peak compressor efficiency while delivering long, reliable service life over the complete spectrum of compressor applications. Our valves are available for most reciprocating compressors, regardless of age, size, type, make, use or pressure rating. Our valves can help you get the very most out of your compressors. Our compressor valves are manufactured exactly as per the O.E.M specifications. Each component of the valve is checked before assembly and each valve assembly is tested for leak proofness. We offer valves of different types as per the O.E.M. specification. Those include

- 1. Ring Type.

- 2. Channel Type.

- 3. Plate Type.

These valves are available for a wide range of pressure upto 3000 bars and compressor capacity upto 10000 cubic meters per hour & are available from sizes of 25 mm to 450 mm in diameter. These valves are used for air compressors as well as gas compressors handling even many corrosive, toxic and flammable gases. Gases handled include Acetylene, Argon, Carbon di-oxide, Chlorine, Hydrogen, L.P.G, Nitrogen, Oxygen, Sulphur di-oxide etc and also gas mixtures. Valve material is selected carefully to suit both lubricated and non-lubricated service. Materials include graded cast iron, carbon steel, stainless steel, bronze etc and all materials are tested for physical and chemical properties. All valves are fully interchangeable with the OEM valves. All assembled valves are leak tested by compressed air and are cleared only if the leakage is within permissible limit. All valves are coated with approved chemicals to prevent rusting or corrosion. Those are then labeled for easy identification and packed properly to ensure that no damage occurs during transit or storage.

Precision valve components to their exacting specifications & standards are offered. They are physically interchangeable with OEM parts and also equal in performance, efficiency & service life.

Precision valve components to their exacting specifications & standards are offered. They are physically interchangeable with OEM parts and also equal in performance, efficiency & service life.

Precision Compressor Parts are offered that makes the reciprocating compressors last longer & leak less. With sincere focus for enhanced performance, we supply critical parts for correct functioning of reciprocating equipments.

- Piston & Rider Rings / Expander Rings / Rider Bands / Pressure Balanced Piston Rings.

- Pressure Packing Rings / Balance Overlapping Tangent Rings / Side Loaded Pressure Rings

- Oil Wiper Rings

- Pressure Breakers / Back up Rings

- Valve Inserts / Buttons / Spring Caps

- PEEK® Valve Plates / PEEK® Poppets

We offer a broad range of tribologically advantageous materials for optimum results. Parts are manufactured using premium base resins with blends such as Carbon Fibre, Glass Fiber, Graphite, Bronze, Ceramic, Molybdenum Disulphide Polyamide, PEEK®, PPS, Silica, Calcium Fluorides, Stainless Steel, Aluminum Alloy & special high strength polymers.

Best suitable for the most challenging operating conditions: chemically inert to highly reactive gases, cryogenic to high operating temperatures, vacuum to high pressure applications like - Ambient Air / Bone dry Nitrogen / Bone dry Oxygen / Pure Air for PET blow molding / Hydrogen / Helium / LPG / CNG / Hydrocarbon Mixtures / Acetylene / Argon / Carbon Dioxide / Ethylene / Propylene / Propane and Isobutene.

Shreyansh offers imported piston rings for reciprocating compressors - the most comprehensive line of piston rings, compression rings, and oil rings available upto 6” bores. Our rings function in sets, usually—a top compression ring, second groove compression (or oil scraper) ring, and oil control ring.

Shreyansh offers imported piston rings for reciprocating compressors - the most comprehensive line of piston rings, compression rings, and oil rings available upto 6” bores. Our rings function in sets, usually—a top compression ring, second groove compression (or oil scraper) ring, and oil control ring.

Top Compression Rings control combustion chamber gases allowing the piston to transfer the energy of the expanding combustion gases, to the crankshaft. These rings also play a major role in the heat transfer process between the piston and cylinder wall.

Second Compression Rings scrape oil and prevent it from reaching the combustion chamber. They also provide a second seal to trap combustion gases and aid in the heat transfer to the cylinder wall.

Oil Control Rings provide uniform pressure through two steel rails assuring positive oil control. The three-piece design allows rails to be manufactured with a small cross sectional area for better conformability to the bores of today’s low-tension, low-friction applications.